Stainless steel laser cutting

Stainless steel laser cutting products basic information:

Workpiece material: stainless steel

Processing Type: stainless steel laser cutting

Processing Product range: metal accessories products

Proofing time: 4-7 days

Processing time: 4-7 days

In the remaining processing capacity: 1000000 (pieces)

Thickness: 2mm

Our spirit of "customer first, better" philosophy, to provide customers with better service, welcomed the new and old customers to negotiate business!

Stainless steel laser cutting Details:

Stainless steel laser cutting, high efficiency, since the transmission characteristics of the laser, and stainless steel laser cutting machine is generally equipped with multiple sets of CNC table, stainless steel laser cutting of the entire cutting process can be fully realized NC. In operation, simply by changing the NC program, you can apply different shapes cut parts, both two-dimensional cut, while achieving a three-dimensional cutting.

Stainless steel laser cutting speed, hard was 1200W laser cutting 2mm thick carbon steel plate, cutting speeds of up to 600cm / min; cut 5mm thick acrylic resin plate, cutting speeds up to 1200cm / min. Material does not require clamping fixed laser cutting stainless steel, can save fixture, but also saves the upper and lower auxiliary material time.

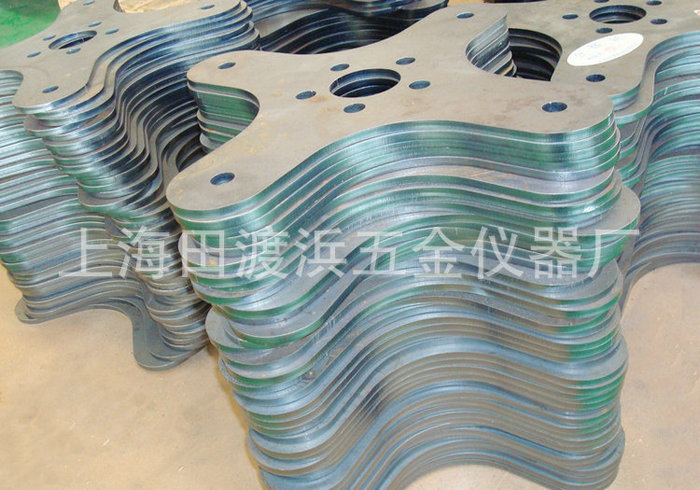

1. Cutting sewing fine: stainless steel laser cutting kerf is generally 0.10 ~ 0.20mm.

2. Smooth cutting surface: stainless steel laser cutting burr-free cutting surfaces, the general control of the surface roughness Ra: 12.5 and above.

3. Speed: stainless steel laser cutting and wire cutting speed is much faster compared to the rate, a rate cut 6mm steel up to 2 m / min.

4. Heat distortion: stainless steel laser cutting laser slotted small, fast, energy concentration, thus cutting the material passed on by small heat, causing deformation of the material is very small.

5. Using computer warehouse automatic control and intelligent discharge system, any curve can be flat and cut, one cut type, no secondary processing, cost-bottom, high efficiency, the use of wide advantages.

6. For large products processing: mold manufacturing large products of high cost, stainless steel laser cutting without any mold manufacturing, and stainless steel laser cutting punching completely avoid the collapse of the material forming the edge, can significantly to reduce production costs to improve product quality.

7. Very suitable for development of new products and shorten the development cycle: Once the product drawings formed immediately can be stainless steel laser cutting, you can get the kind of new products in the shortest possible time.

8. Saving materials: stainless steel laser cutting using computer programming, can be of different shapes Nesting material, maximize the utilization of the material.

9. Laser cutting for stainless steel materials: laser can steel, stainless steel, aluminum alloy plate, carbide processing.

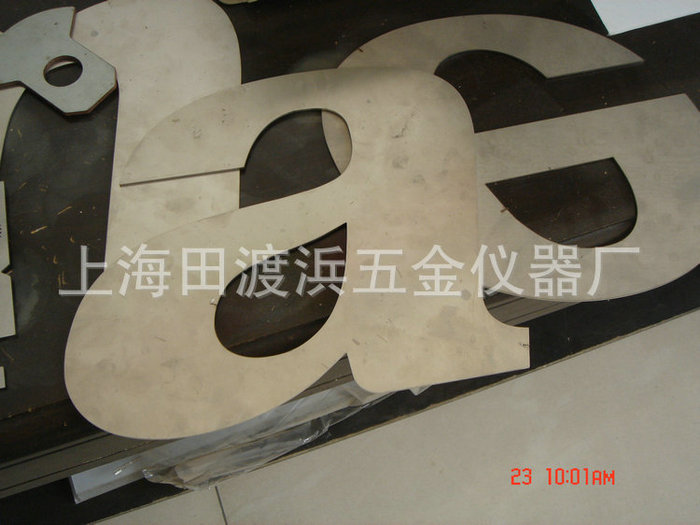

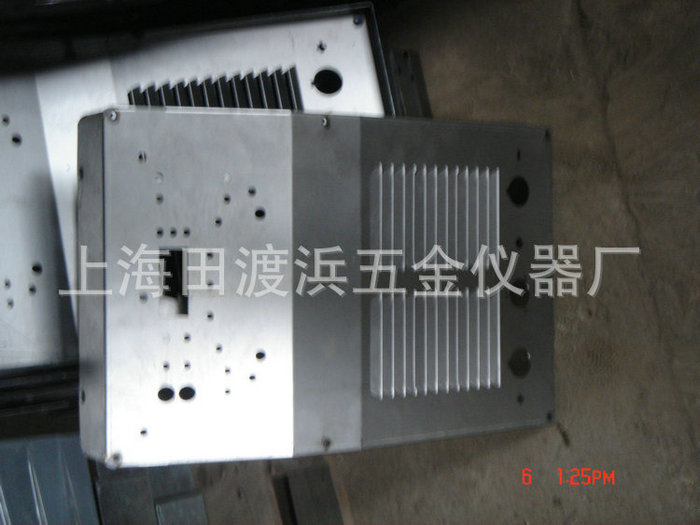

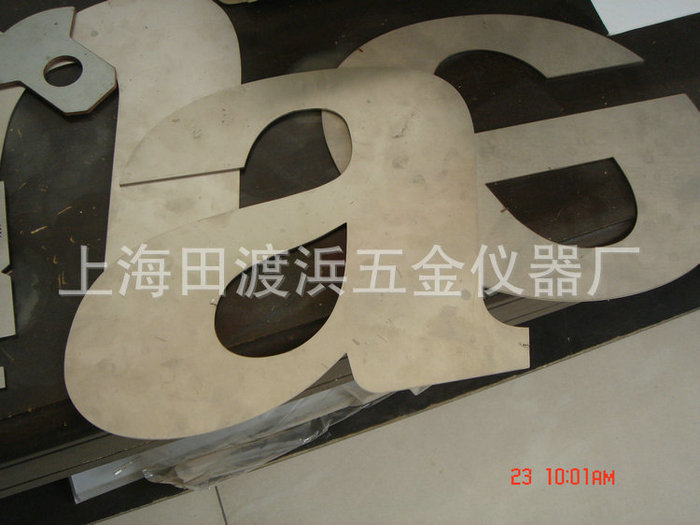

Stainless steel laser cutting products displayed: