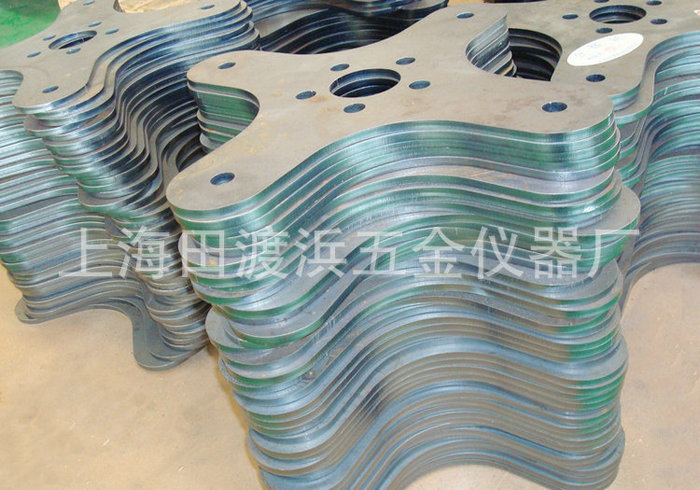

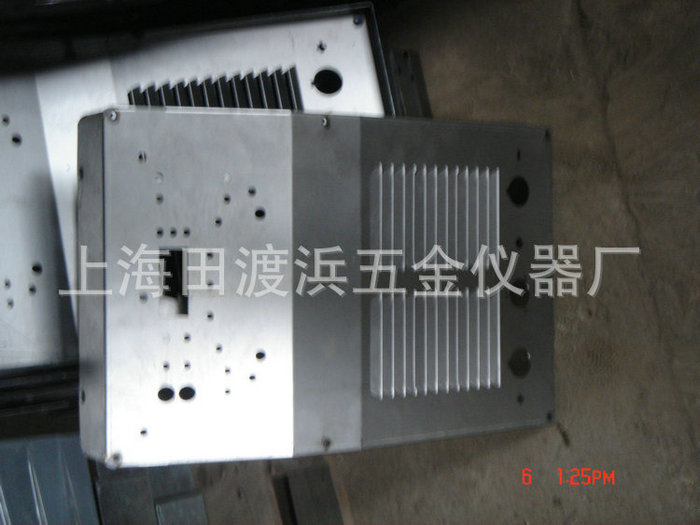

Sheet metal processing

Sheet Metal Products basic information:

Sheet Metal Material: cold rolled sheet

Sheet metal thickness: 2 (mm)

Processing Dimensions / L * W * H: 1000x1200x2000 (mm)

Molded parts: Chassis

Cutting way: shears

Tolerance: 0.1

Processing Step: sheet metal processing involving flanging, embedded flanging, bending, reinforcement ribs, stamping, punching, cutting, fillet, molding, and other processes to expand

Surface treatment: according to customer requirements

Surface roughness: smooth

Proofing time: 4-7 days

Processing time: 4-7 days

Maximum annual processing capacity: 1 million

Applications: sheet metal processing used in telecommunications, bridges, electricity, industrial equipment, public facilities, other industries

Sheet metal processing Details:

Cutting sheet metal processing a variety of ways, mainly in the following ways

①. Sheet Metal cutting shears ways: using a shear machine strip simple materials and parts, it is primarily to prepare for the forming mold blanking processing, low cost, precision of less than 0.2, but only non-porous non-processed Cutaway The strip or bulk.

②. Punching sheet metal processing cutting mode: The use of punch one or more steps in the flat parts stamping sheet metal parts will be formed after the commencement of various shapes of materials and parts, the advantage of cost and shorter, high efficiency, high precision, cost low, suitable for mass production, but to design the mold.

③. NC CNC sheet metal processing cutting mode of cutting, first time to write NC NC cutting programs, use programming software, will be drawn into an expanded view of the preparation of NC machine tools pull a few recognizable program, let these programs step Punching knife in the flat shape of the plate member each structure, but its structure by the tool structure actions, low cost, precision to 0.15.

④. By way of laser cutting sheet metal processing material, the use of laser cutting method, in a large flat structural shape will be cut out of their flat, with the need to prepare the same NC laser cutting program, which can be flat pieces of a variety of complex shapes high cost, precision 0.1.

⑤. Sheet Metal Cutting Saw ways: mainly used under aluminum, square tube, showing the pipe, round bars and the like, low cost, low accuracy.

Sheet metal processing products displayed: